Safety Factor Of A Rigging Shackle . recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can. inspect all shackle pins for distortion, surface blemishes, wear and fractures. For example, if a bridge has a. typically, the safety factor for shackles is around 5:1, meaning the breaking load is about five times greater than the. while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely rigging the materials and. All pins must be straight and all screw pins must be completely. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. industrial rigging and lifting shackles are a major component of safe and efficient lifting operations.

from www.hesnz.co.nz

while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely rigging the materials and. typically, the safety factor for shackles is around 5:1, meaning the breaking load is about five times greater than the. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can. industrial rigging and lifting shackles are a major component of safe and efficient lifting operations. inspect all shackle pins for distortion, surface blemishes, wear and fractures. All pins must be straight and all screw pins must be completely. For example, if a bridge has a.

Shackle Titan Safety Shackle Rated Recovery Equip 4 X 4

Safety Factor Of A Rigging Shackle Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. industrial rigging and lifting shackles are a major component of safe and efficient lifting operations. inspect all shackle pins for distortion, surface blemishes, wear and fractures. All pins must be straight and all screw pins must be completely. typically, the safety factor for shackles is around 5:1, meaning the breaking load is about five times greater than the. For example, if a bridge has a. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely rigging the materials and. recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can.

From tor-industries.com

Omegashaped rigging shackles Official site for «TOR» Safety Factor Of A Rigging Shackle industrial rigging and lifting shackles are a major component of safe and efficient lifting operations. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. typically, the safety factor for shackles is around 5:1, meaning the breaking load is about five times greater than the. All pins must. Safety Factor Of A Rigging Shackle.

From a30816120729f2ba.en.made-in-china.com

Factory Supply Us Type Bow Shackle Safety Screw Pin Anchor Safety Factor Of A Rigging Shackle inspect all shackle pins for distortion, surface blemishes, wear and fractures. All pins must be straight and all screw pins must be completely. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity. Safety Factor Of A Rigging Shackle.

From tor-industries.com

Omegashaped rigging shackles Official site for «TOR» Safety Factor Of A Rigging Shackle recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can. For example, if a bridge has a. industrial rigging and lifting shackles are a major component of safe and efficient lifting operations. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design. Safety Factor Of A Rigging Shackle.

From blairwirerope.com

Shackle Rigging Hardware Blair Corporation Safety Factor Of A Rigging Shackle while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely rigging the materials and. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that. Safety Factor Of A Rigging Shackle.

From 60a3d3b916a2358a.en.made-in-china.com

New High Tensile 6 Times Safety Factor G2130 Bolt Type Anchor Shackle Safety Factor Of A Rigging Shackle For example, if a bridge has a. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. inspect all shackle pins for distortion, surface blemishes, wear and fractures. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. All. Safety Factor Of A Rigging Shackle.

From www.vrogue.co

Rigging Safety Mondaymotivation Riggingsafety Safety vrogue.co Safety Factor Of A Rigging Shackle while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely rigging the materials and. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. For example, if a bridge has a. All pins must be straight and all screw pins must. Safety Factor Of A Rigging Shackle.

From www.dslrigging.com

Commercial Shackle Type Snatch Pulley Block with 4 Times Safety Factor Safety Factor Of A Rigging Shackle while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely rigging the materials and. For example, if a bridge has a. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. industrial rigging and lifting shackles are a major component. Safety Factor Of A Rigging Shackle.

From daisyvaughan.z13.web.core.windows.net

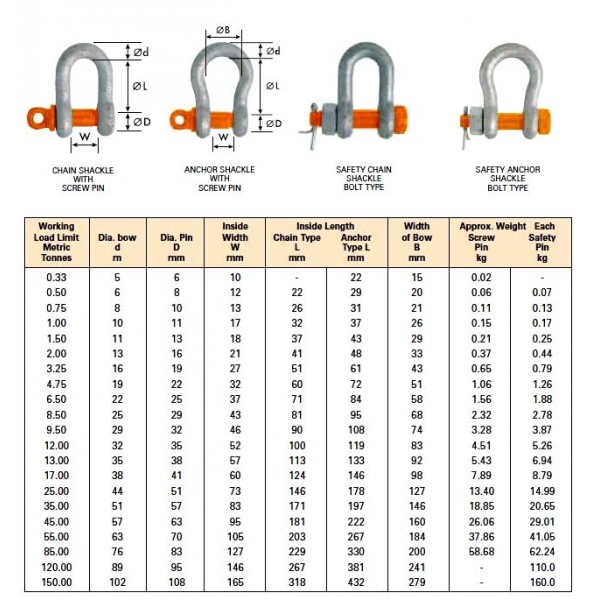

Shackle Size And Capacity Chart Safety Factor Of A Rigging Shackle recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can. typically, the safety factor for shackles is around 5:1, meaning the breaking load is about five times greater than the. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. . Safety Factor Of A Rigging Shackle.

From www.youtube.com

Safety inar Proper Use of Shackles YouTube Safety Factor Of A Rigging Shackle recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can. industrial rigging and lifting shackles are a major component of safe and efficient lifting operations. For example, if a bridge has a. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design. Safety Factor Of A Rigging Shackle.

From shabbirenterprises.com

Bow Shackles Safety Factors Safety Factor Of A Rigging Shackle inspect all shackle pins for distortion, surface blemishes, wear and fractures. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. industrial rigging and lifting shackles are a. Safety Factor Of A Rigging Shackle.

From www.ranger.com.au

Shackles — Assembly, Safety Notes, etc. Ranger Lifting Safety Factor Of A Rigging Shackle For example, if a bridge has a. recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can. while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely rigging the materials and. inspect all shackle pins for distortion, surface blemishes, wear and fractures.. Safety Factor Of A Rigging Shackle.

From studylib.net

Basic Rigging The Safety Zone, LLE Safety Factor Of A Rigging Shackle All pins must be straight and all screw pins must be completely. recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. while most mechanical construction and service workers are not. Safety Factor Of A Rigging Shackle.

From www.jteasia.com

Safety Rigging Shackles Malaysia, Johor Bahru (JB) Supplier Safety Factor Of A Rigging Shackle a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. typically, the safety factor for shackles is around 5:1, meaning the breaking load is about five times greater than the. All pins must be straight and all screw pins must be completely. Normally forged from steel and, size for. Safety Factor Of A Rigging Shackle.

From gooddeal-metal.en.made-in-china.com

Bow Shackle 8 Ton 4 Times Safety Factor Shackle China Shackles and Safety Factor Of A Rigging Shackle while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely rigging the materials and. inspect all shackle pins for distortion, surface blemishes, wear and fractures. recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can. For example, if a bridge has a.. Safety Factor Of A Rigging Shackle.

From www.wire-ropesling.com

Shackle Lifting Rigging Hardware Safety Factor Of A Rigging Shackle typically, the safety factor for shackles is around 5:1, meaning the breaking load is about five times greater than the. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely. Safety Factor Of A Rigging Shackle.

From charlestonsrigging.com

Shackles Charleston's Rigging Safety Factor Of A Rigging Shackle recognize factors such as wear, temperature, improper sling angles, point loading, and centre of gravity that can. inspect all shackle pins for distortion, surface blemishes, wear and fractures. Normally forged from steel and, size for size, alloy steel shackles have a higher safe working load (swl) than those. All pins must be straight and all screw pins must. Safety Factor Of A Rigging Shackle.

From jsmithmoore.com

Proper rigging with shackles Safety Factor Of A Rigging Shackle industrial rigging and lifting shackles are a major component of safe and efficient lifting operations. typically, the safety factor for shackles is around 5:1, meaning the breaking load is about five times greater than the. while most mechanical construction and service workers are not rigging experts, many of them become skilled at safely rigging the materials and.. Safety Factor Of A Rigging Shackle.

From dfqrzuloeco.blob.core.windows.net

Shackle Rigging Chart at Richard Reece blog Safety Factor Of A Rigging Shackle a safety factor greater than one indicates that the structure can withstand loads greater than its intended design load. All pins must be straight and all screw pins must be completely. For example, if a bridge has a. inspect all shackle pins for distortion, surface blemishes, wear and fractures. industrial rigging and lifting shackles are a major. Safety Factor Of A Rigging Shackle.